Section 3: Planning and Building the Neighborhood

By Dan Reiff, October 2009

The Maloney Heights, Inc. investor group consisted of architects, engineers and construction professionals, and their combined abilities provided all the necessary experience required to plan and build a neighborhood from scratch. Florist Brockway Crouch and others contributed financial backing. Charles I. Barber had been chief architect for TVA in the mid 1930s and designed housing for the town of Norris. Barber also served as chairman of the Knox County Planning Commission, and William Cain had served on the Knoxville City Council.

Maloney Heights, Inc. Shareholders (Shares)

1. D. West Barber, President (Barber & McMurry) 6

2. Charles I. Barber (Barber & McMurry) 6

3. Wylie A. Bowmaster (TVA) 6

4. Brockway Crouch (Crouch Florist) 9

5. William H. Cain (Chavannes Lumber Co. City Council 1938-41) 6

6. Osborne H. Graves (TVA) 3

7. Addison Hook (TVA) 6

8. J. W. Warren (Southern Cast Stone Co.) 6

9. E. Arnold Sunstrom, Treasurer (TVA) / Ludmilla B. Sunstrom 5

10. J. O. Klepper 2.5

Additional Investors

11. Quinnie M. Klepper 2.5

12. Alice A. Bays (719 Pine Street, Johnson City, TN) 3

13. Robert L. Anderson (719 Pine Street, Johnson City, TN) 3

Trustee

Robert S. Young, Jr., (Law Firm of Lindsay, Young, and Young)

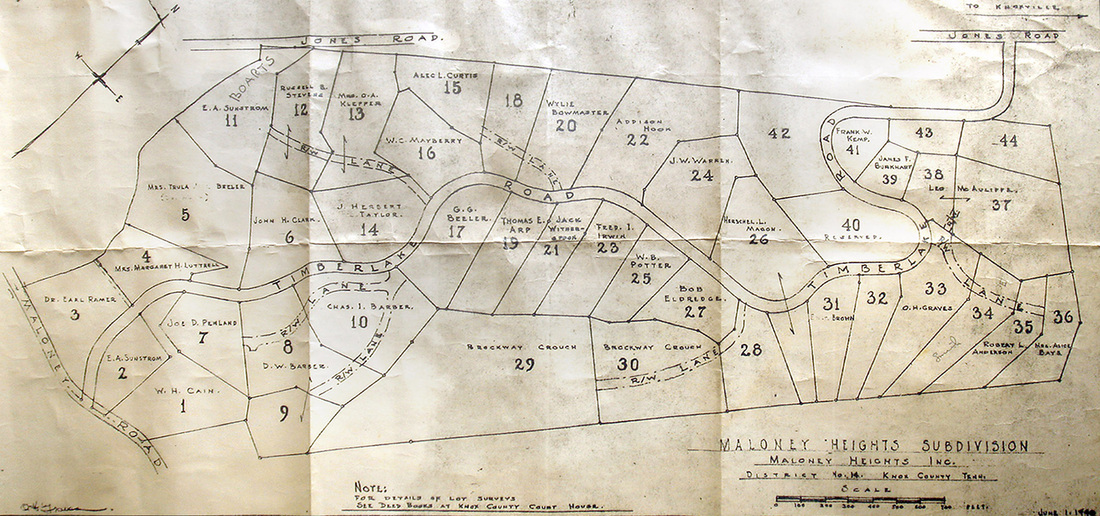

University of Tennessee faculty were connected to the TVA group through project collaboration between UT and TVA, through the hiking club, and as neighbors living along Woodson Drive. While the investors had first pick of the lots, many of the remaining lots were reserved by UT professors. Figure 3-A shows the 1948 lot reservation map.

The Maloney Heights, Inc. investor group consisted of architects, engineers and construction professionals, and their combined abilities provided all the necessary experience required to plan and build a neighborhood from scratch. Florist Brockway Crouch and others contributed financial backing. Charles I. Barber had been chief architect for TVA in the mid 1930s and designed housing for the town of Norris. Barber also served as chairman of the Knox County Planning Commission, and William Cain had served on the Knoxville City Council.

Maloney Heights, Inc. Shareholders (Shares)

1. D. West Barber, President (Barber & McMurry) 6

2. Charles I. Barber (Barber & McMurry) 6

3. Wylie A. Bowmaster (TVA) 6

4. Brockway Crouch (Crouch Florist) 9

5. William H. Cain (Chavannes Lumber Co. City Council 1938-41) 6

6. Osborne H. Graves (TVA) 3

7. Addison Hook (TVA) 6

8. J. W. Warren (Southern Cast Stone Co.) 6

9. E. Arnold Sunstrom, Treasurer (TVA) / Ludmilla B. Sunstrom 5

10. J. O. Klepper 2.5

Additional Investors

11. Quinnie M. Klepper 2.5

12. Alice A. Bays (719 Pine Street, Johnson City, TN) 3

13. Robert L. Anderson (719 Pine Street, Johnson City, TN) 3

Trustee

Robert S. Young, Jr., (Law Firm of Lindsay, Young, and Young)

University of Tennessee faculty were connected to the TVA group through project collaboration between UT and TVA, through the hiking club, and as neighbors living along Woodson Drive. While the investors had first pick of the lots, many of the remaining lots were reserved by UT professors. Figure 3-A shows the 1948 lot reservation map.

Survey and Site Plan

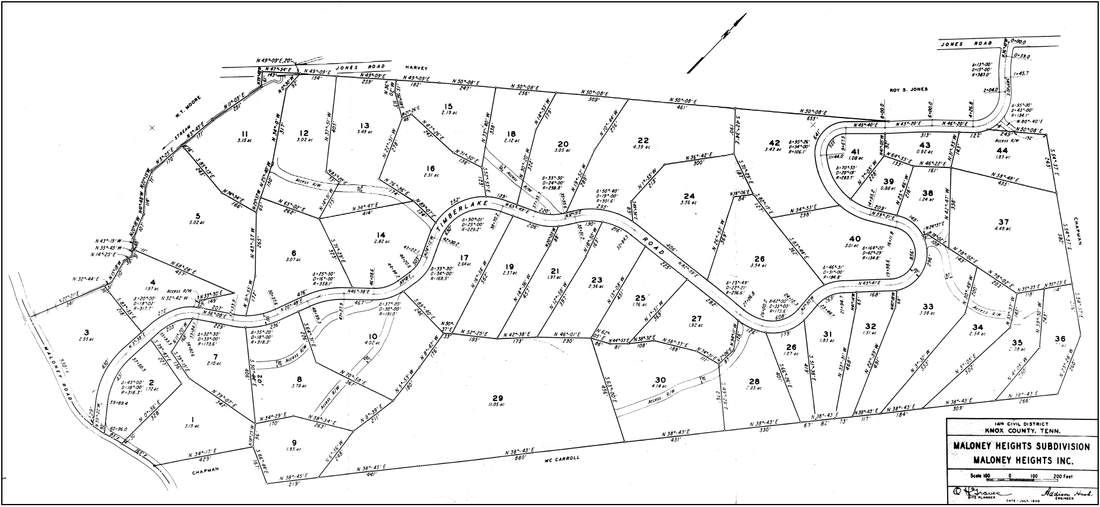

Osborn H. Graves, a landscape architect with TVA and one of the Maloney Heights Inc. investors, served as site planner for the development. He walked the tract of Chapman’s ridge in 1947 and staked out prime house sites with mountain and lake views. The steep hillsides and deep valleys presented challenges, but Graves – along with Addison Hook, a civil engineer with TVA – designed a unique configuration of 44 lots, utilizing a main road and five side lanes (access right-of-ways that cut through other lots) to reach 16 of the more remote sites. Permission was granted for back-around spaces to be substituted at the termination of the side roads instead of 100' cul-de-sacs specified by Knox County Planning Commission. The planning concept worked well with the natural topography, requiring limited infill and leveling of the landscape. The 1948 site plan filed with Knox County is shown in Figure 3-C.

The Maloney Heights Inc. group formed a planning committee to oversee the design and placement of all homes. In the Subdivision Restrictions, number 5 states:

“No building shall be erected, placed, or altered on any building plot in this subdivision until the building plans, specifications and plot plan showing the location of such building or alteration have been approved in writing as to conformity and harmony of external design with existing structures in the subdivision, and as to location of the building with respect to topography and finished ground elevation…”

The result of this oversight is a neighborhood of unpretentious homes that fit the landscape, appearing unassuming from the road, but often with stunning views from within.

“No building shall be erected, placed, or altered on any building plot in this subdivision until the building plans, specifications and plot plan showing the location of such building or alteration have been approved in writing as to conformity and harmony of external design with existing structures in the subdivision, and as to location of the building with respect to topography and finished ground elevation…”

The result of this oversight is a neighborhood of unpretentious homes that fit the landscape, appearing unassuming from the road, but often with stunning views from within.

According to a letter from D.W. Barber to the postmaster, dated December 12, 1949, The first nine homes built (as of Dec 5, 1949) were:

Lot Street # Owner Family members

1 3621 Maloney Will H. Cain 3

8 3712 Timberlake D.W. Barber 2

14 3715 Timberlake Herbert Taylor 3

16 3613 Timberlake C.L. Schenck 3

20 3601 Timberlake Wylie Bowmaster 7

25 3516 Timberlake W. B. Potter, Jr. 2

26 3425 Timberlake Herschel L. Macon 4

39 3320 Timberlake James F. Burkhart 4

41 3316 Timberlake Frank W. Kemp 2

By 1953, 27 homes had been built. By 1962 the remaining houses in the Maloney Heights subdivision (as well as the adjacent homes on the northern end of Timberlake, which later became part of the Timberlake Community Club) were constructed, with the exception of Dean Barber’s home at 3704 and Charles and Janet Dempster’s home at 3704 Timberlake. (Complete details of ownership and build dates for all properties are listed in Appendix A, Property Owner List.)

Not all of the original investors built and lived at their reserved lots. In one of the final letters of correspondence to the Maloney Heights Inc. investors as the corporation disbanded, dated March 10, 1953, D. W. Barber wrote the group, “Brock and I assure you that those of you who are not now living on Timberlake Road are missing something. It is a very fine neighborhood.”

Lot Street # Owner Family members

1 3621 Maloney Will H. Cain 3

8 3712 Timberlake D.W. Barber 2

14 3715 Timberlake Herbert Taylor 3

16 3613 Timberlake C.L. Schenck 3

20 3601 Timberlake Wylie Bowmaster 7

25 3516 Timberlake W. B. Potter, Jr. 2

26 3425 Timberlake Herschel L. Macon 4

39 3320 Timberlake James F. Burkhart 4

41 3316 Timberlake Frank W. Kemp 2

By 1953, 27 homes had been built. By 1962 the remaining houses in the Maloney Heights subdivision (as well as the adjacent homes on the northern end of Timberlake, which later became part of the Timberlake Community Club) were constructed, with the exception of Dean Barber’s home at 3704 and Charles and Janet Dempster’s home at 3704 Timberlake. (Complete details of ownership and build dates for all properties are listed in Appendix A, Property Owner List.)

Not all of the original investors built and lived at their reserved lots. In one of the final letters of correspondence to the Maloney Heights Inc. investors as the corporation disbanded, dated March 10, 1953, D. W. Barber wrote the group, “Brock and I assure you that those of you who are not now living on Timberlake Road are missing something. It is a very fine neighborhood.”

Architecture

With two principals of the Barber & McMurry architectural firm in the investor group (cousins D.W. and Charles I. Barber), it’s not surprising that a few homes in the neighborhood were designed by the firm. There may be others, but known Barber & McMurry homes include:

Address 2009 Owner Built by

3404 Timberlake Duckett Fred Smith

3605 Timberlake Key Alvin Nielsen

3704 Timberlake McLemore Dean Barber

3712 Timberlake Icove D. W. Barber

3716 Timberlake Pritcher Joe Penland

3722 Timberlake Thomson A. W. (Sandy) Cain

3621 Maloney Burr W. H. Cain

Barber & McMurry residential designs are common in other areas of Knoxville developed from 1915 through World War II. A report prepared by the Knoxville Historic Zoning Commission for the Lyons View Pike District contains an elegant description of Charles Barber’s architectural style:

Address 2009 Owner Built by

3404 Timberlake Duckett Fred Smith

3605 Timberlake Key Alvin Nielsen

3704 Timberlake McLemore Dean Barber

3712 Timberlake Icove D. W. Barber

3716 Timberlake Pritcher Joe Penland

3722 Timberlake Thomson A. W. (Sandy) Cain

3621 Maloney Burr W. H. Cain

Barber & McMurry residential designs are common in other areas of Knoxville developed from 1915 through World War II. A report prepared by the Knoxville Historic Zoning Commission for the Lyons View Pike District contains an elegant description of Charles Barber’s architectural style:

- Barber’s designs were carefully considered expressions of function and character, not mere anachronism. The various elements of each design were organized for harmony and for the value of contrast, and each element was usually given expressive character. In his houses, chimneys and fireplaces were often emphasized, and the roofs of slate or tile had appealing texture and color. Walls, whether of stone, brick or wood, were carefully designed for the same qualities, and all-important openings were given prominence by their placing or ornament. Compositions were typically asymmetrical, but there was no straining for picturesque effect. Each element seemed naturally to belong where Barber placed it. Some Barber designs had monumental character, but more often he preferred an unasserted charm and a modest scale.

|

|

|

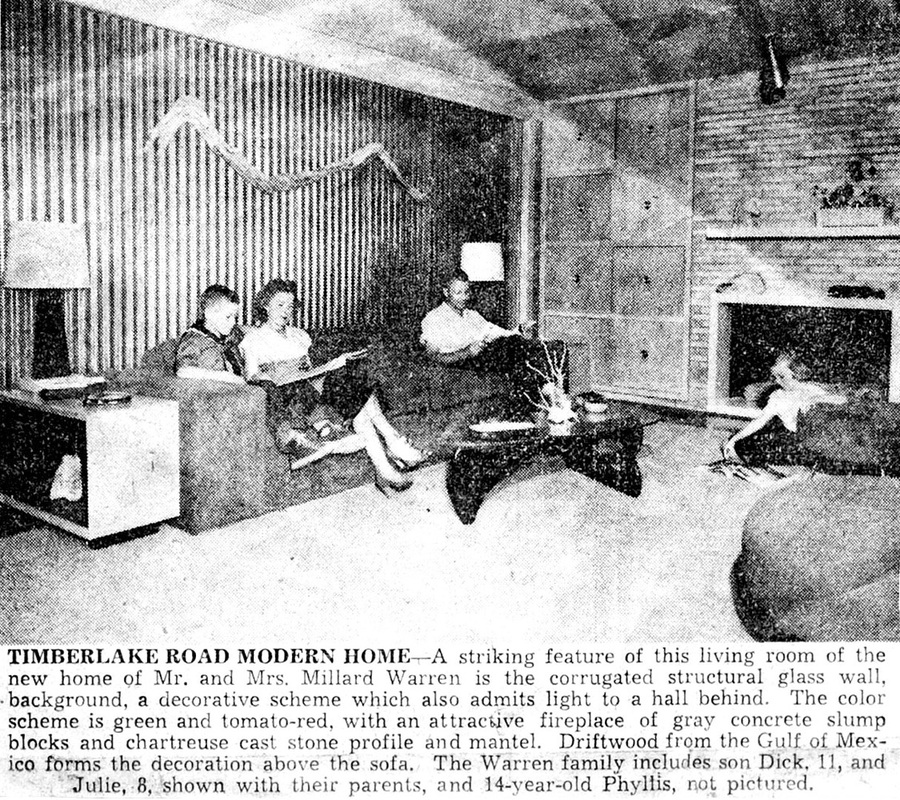

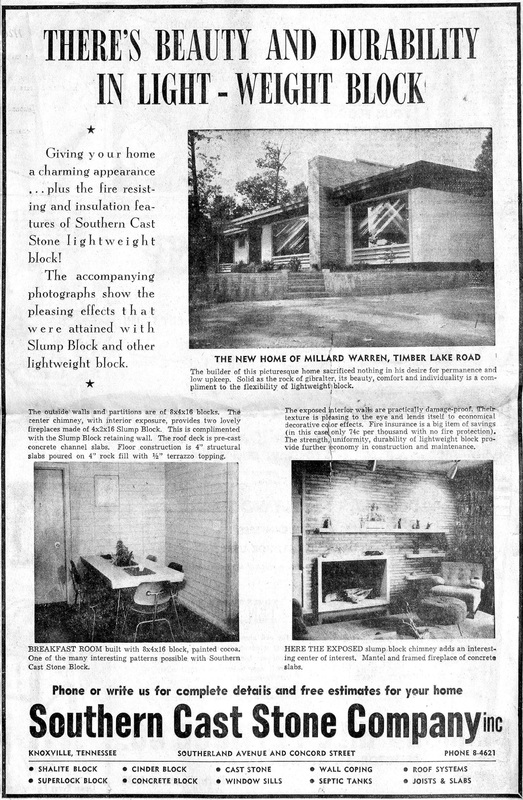

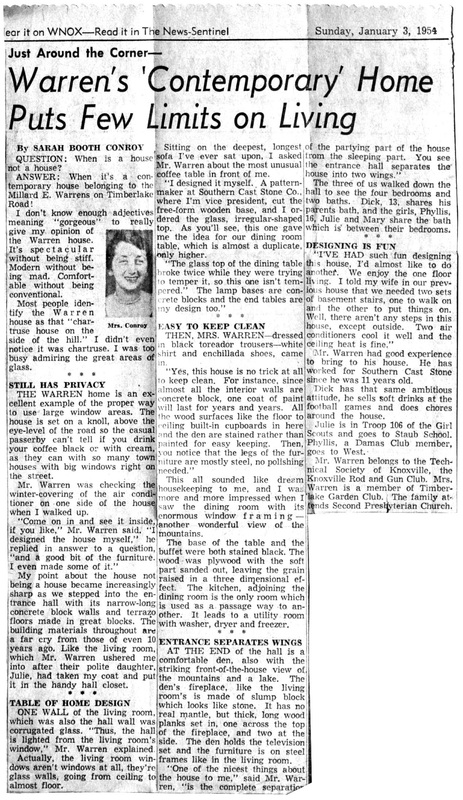

Some home-owners – TVA engineers, professors and builders – utilized their own skills to design and build their homes. Wiley Bowmaster, Robert Brown, O. A. Graves, and Homer Johnson were known to have had a hand in the design and construction of their homes. Fred Smith used his carpentry skills to add built-ins to his home at 3404. Millard Warren designed and built his home and used it as a showcase for materials from his Southern Cast Stone Company. In later years, several future homeowners would make modifications and additions, resulting in impressive, sprawling estates. Appendix C lists some of the many changes that were made to the original homes over the years. The tradition of owner-constructed homes continued into the 21st Century when Charles and Janet Dempster completed their home at 3701 Timberlake in 2006, the most recent home built.

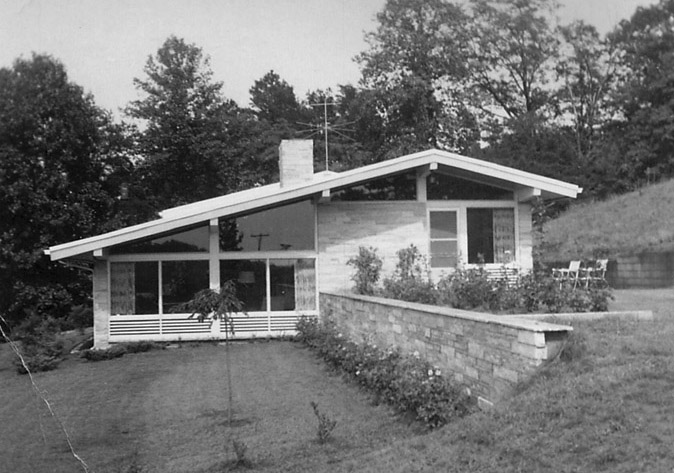

A few houses in the Timberlake neighborhood stand out architecturally and have been featured in magazines or newspaper articles. The home at 3701 Maloney – designed by Knoxville architect, Raymond Guay – was commissioned by Dr. Lou Hefley and her husband Donald McCGrath with specific functions in mind (its history is explained by Walter Brott in Part II of the Timberlake History Project). Two other homes, exemplifying mid century modernism style, include the Warren house at 3517 and the Hill house at 3600 Montlake.

A few houses in the Timberlake neighborhood stand out architecturally and have been featured in magazines or newspaper articles. The home at 3701 Maloney – designed by Knoxville architect, Raymond Guay – was commissioned by Dr. Lou Hefley and her husband Donald McCGrath with specific functions in mind (its history is explained by Walter Brott in Part II of the Timberlake History Project). Two other homes, exemplifying mid century modernism style, include the Warren house at 3517 and the Hill house at 3600 Montlake.

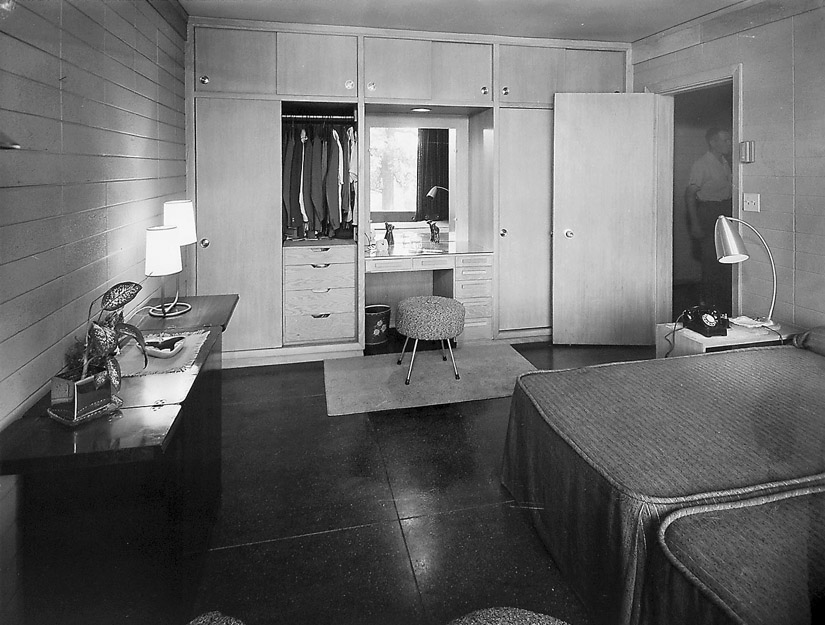

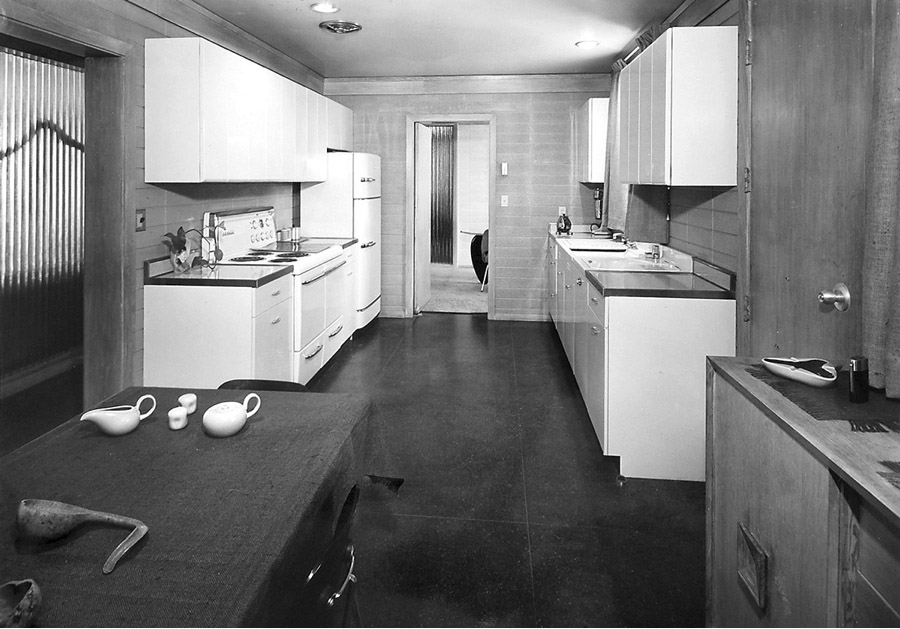

Warren House – 3417 Timberlake Drive

Millard Warren began construction of the house on February 9, 1950, and his family moved in on March 9, 1951. Three generations of the Warren family have since resided in the home. Newspaper clippings and photographs on the following pages describe and illustrate the unique design and construction of the house.

Photos and clippings of the Warren House: (click images to enlarge)

Photos and clippings of the Warren House: (click images to enlarge)

|

|

|

Way (Hill) House, 3600 Montlake Drive

Mark and Cathy Hill bought the property at 3600 Montlake in 2003 and have become exemplary stewards of the unique home, preserving period integrity through structural updates and décor. They painstakingly researched the complicated (and sometimes tragic) history of the property and eventually identified the architect as Herbert Millkey, Sr., of Atlanta, Georgia. Millkey was a modernist architect recognized mainly for his commercial building designs. The house at 3600 Montlake is one of very few residences he designed — commissioned by his friend, William Way, in 1954.

William Way was founder and head of the Transportation Department at the University of Tennessee. He and his wife, Dayis, purchased Maloney Heights Lot 11 in 1951 from Robert and Peg Boarts, (The Boarts’s in turn, purchased the Taylor residence at 3715 Timberlake). Construction of the Way’s home was completed in 1955, and William died of a heart attack in the house a year later. A description of the architecture and recent and vintage photos collected by the Hills are shared below. More of the Hill’s research on their property history is available in Part II of the Timberlake History Project.

William Way was founder and head of the Transportation Department at the University of Tennessee. He and his wife, Dayis, purchased Maloney Heights Lot 11 in 1951 from Robert and Peg Boarts, (The Boarts’s in turn, purchased the Taylor residence at 3715 Timberlake). Construction of the Way’s home was completed in 1955, and William died of a heart attack in the house a year later. A description of the architecture and recent and vintage photos collected by the Hills are shared below. More of the Hill’s research on their property history is available in Part II of the Timberlake History Project.

The third owners of the “Millkey-Way” (Hill) House were Richard and Joanne Freeman. In 1979 they added a swimming pool to the southwest end of the home and remodeled the interior. The above photo, showing the pool, was featured in a calendar produced by Knox Heritage, and their description accompanying the photo aptly describes the home’s architecture:

This house is an airy glass pavilion suspended beneath a unique butterfly roof. One of the few Knoxville examples of true mid-century modern architecture, it embodies the forward-looking optimism of its time, and provides its current owners with an uplifting and inspiring refuge from their busy twenty-first century lifestyle.

Photos of the Way/Hill home, then and now: (click to enlarge)

This house is an airy glass pavilion suspended beneath a unique butterfly roof. One of the few Knoxville examples of true mid-century modern architecture, it embodies the forward-looking optimism of its time, and provides its current owners with an uplifting and inspiring refuge from their busy twenty-first century lifestyle.

Photos of the Way/Hill home, then and now: (click to enlarge)

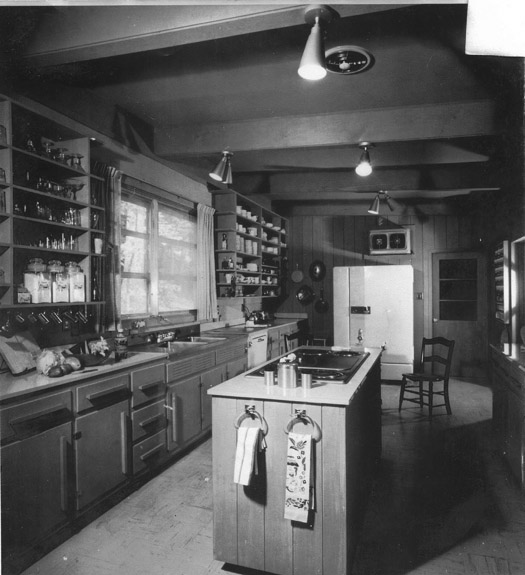

Construction

Homes in the neighborhood contained features popular during the 1950s: hardwood floors, steel or aluminum single paned windows (often replaced), fireplaces, pocket doors, open living areas, small bathrooms, and small or galley-style kitchens. Built on hillsides, most homes have walk-out basement levels and decks and/or porches. See Appendix C for a brief discussion on architectural changes (e.g., porch reconstruction/modification) to the homes.

Neighbor Jack Witherspoon owned a company that manufactured ceil heating, so many of the homes utilized the electrical heating system. Ceil heat is electric radiant ceiling panels that provide heating through radiant heat transfer. With radiant heating, people are warmed directly, in the same way as they are by the sun on a cool day. Radiant panels were used to provide zoned heat, requiring a thermostat for each zone, which was generally one room per zone. Radiant heat panels work by warming objects (including occupants) directly, instead of warming the air, and reportedly allow a lower room air temperature than conventional forced air systems by concentrating heating on the occupants rather than heating the entire room. Therefore, panel placement is important for optimal comfort. It is now thought that ceil heat has become too expensive to operate; a second drawback with the old systems of ceil heat was that a water leak of some sort on non-lathe and plaster ceilings caused the entire ceiling containing the heat coils to collapse.

Roofs architecture of the Timberlake homes vary, with some pitched – both gabled and hipped – and some flat. A few houses are faced with red brick over a wood frame, which, in some instances, has been painted.

Homes in the neighborhood contained features popular during the 1950s: hardwood floors, steel or aluminum single paned windows (often replaced), fireplaces, pocket doors, open living areas, small bathrooms, and small or galley-style kitchens. Built on hillsides, most homes have walk-out basement levels and decks and/or porches. See Appendix C for a brief discussion on architectural changes (e.g., porch reconstruction/modification) to the homes.

Neighbor Jack Witherspoon owned a company that manufactured ceil heating, so many of the homes utilized the electrical heating system. Ceil heat is electric radiant ceiling panels that provide heating through radiant heat transfer. With radiant heating, people are warmed directly, in the same way as they are by the sun on a cool day. Radiant panels were used to provide zoned heat, requiring a thermostat for each zone, which was generally one room per zone. Radiant heat panels work by warming objects (including occupants) directly, instead of warming the air, and reportedly allow a lower room air temperature than conventional forced air systems by concentrating heating on the occupants rather than heating the entire room. Therefore, panel placement is important for optimal comfort. It is now thought that ceil heat has become too expensive to operate; a second drawback with the old systems of ceil heat was that a water leak of some sort on non-lathe and plaster ceilings caused the entire ceiling containing the heat coils to collapse.

Roofs architecture of the Timberlake homes vary, with some pitched – both gabled and hipped – and some flat. A few houses are faced with red brick over a wood frame, which, in some instances, has been painted.

Figure 3-X: Transition from newer wood to block

Several original owners had engineering backgrounds, and their homes in particular were solidly constructed. The Robert Brown house at 3308 has been described as being “built like a TVA dam using steel beams and concrete.”

What at first glance appears to be eight-inch wooden siding on many houses is actually a unique concrete block, designed and stacked to look like traditional siding. Southern Cast Stone Co. supplied “Knox Blocks” and H.C. Fonde & Sons reportedly was involved in some of the construction. The concrete blocks used in early construction of Timberlake homes are no longer available, and additions to the concrete block homes have used various building materials to try to blend with the original look. A reinforcing medium of wire mesh and mortar between the concrete blocks was used on approximately every third course for lateral strength. It is interesting to note that the Warren house, profiled earlier in this section, did not use “Knox Blocks,” but instead used half-high 3‑inch blocks, although Mr. Warren owned the Southern Cast Stone Company.

For the houses that have a partial submerged lower level, the concrete blocks used were sufficiently porous as to allow dampness into the lower levels. While some homes did use a water proofing material available at that time, the mastic mediums used did not include a membrane and are not as effective as today’s products for water proofing concrete surfaces. It has been an expensive proposition to resolve the dampness problem in these homes as the clay dirt abutting basement walls has had to be removed with a backhoe and without damaging the structure in order to install superior waterproofing. Many of the houses with a dampness problem in the lower level have employed French drains (i.e., a trench with gravel or drainpipe that directs water away from a moisture laden area) to solve the problem, which is a less costly fix than excavating the soil against the lower level structure.

What at first glance appears to be eight-inch wooden siding on many houses is actually a unique concrete block, designed and stacked to look like traditional siding. Southern Cast Stone Co. supplied “Knox Blocks” and H.C. Fonde & Sons reportedly was involved in some of the construction. The concrete blocks used in early construction of Timberlake homes are no longer available, and additions to the concrete block homes have used various building materials to try to blend with the original look. A reinforcing medium of wire mesh and mortar between the concrete blocks was used on approximately every third course for lateral strength. It is interesting to note that the Warren house, profiled earlier in this section, did not use “Knox Blocks,” but instead used half-high 3‑inch blocks, although Mr. Warren owned the Southern Cast Stone Company.

For the houses that have a partial submerged lower level, the concrete blocks used were sufficiently porous as to allow dampness into the lower levels. While some homes did use a water proofing material available at that time, the mastic mediums used did not include a membrane and are not as effective as today’s products for water proofing concrete surfaces. It has been an expensive proposition to resolve the dampness problem in these homes as the clay dirt abutting basement walls has had to be removed with a backhoe and without damaging the structure in order to install superior waterproofing. Many of the houses with a dampness problem in the lower level have employed French drains (i.e., a trench with gravel or drainpipe that directs water away from a moisture laden area) to solve the problem, which is a less costly fix than excavating the soil against the lower level structure.